Hızlı Ayrıntılar

Durum: Yeni

Anma Gücü: 7.5kw

Boyut (U*G*Y): 2100*3200*1600

Ağırlık: 1000kg

Belgelendirme: ce iso

1 yıl garanti

Sağlanan Satış Sonrası Hizmet: Yurtdışı hizmet amaçlı kullanılabilir makine mühendisleri

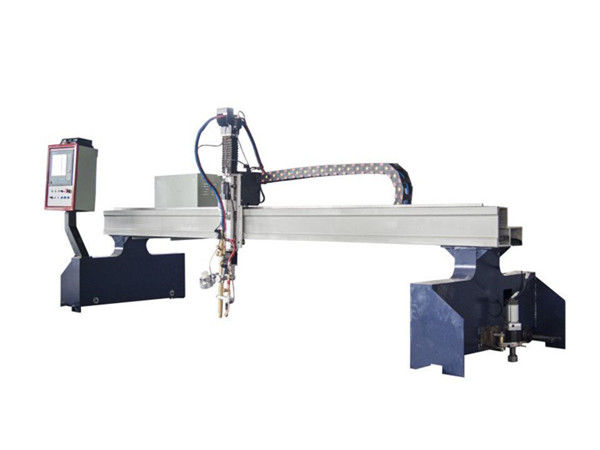

Ürün adı: küçük portal cnc pantograf metal kesme makinası/cnc plazma kesici

Renk: özelleştirilebilir

Kesme malzemesi: Metal Paslanmaz Çelik Karbon Çelik Alüminyum

Uygulama: Sac kesme

Ekran: LCD

Kesme hızı: 0-8000mm / dak

Kesme kalınlığı: 0-200mm

Plazma kaynağı: Jiangsu Jiusheng

Yazılım: STARCAM

CNC sistemi: F2300B

Ana parçalar

1. Işın doğrusal kılavuz kullanır.

2.Beam, kutu tipi yapı ve portal çerçeveyi benimser. Kaynaktan sonra, artık gerilmeyi gidermek ve deformasyona uğramamasını sağlamak için titreşim stres giderme işlemi kullanmak.

3.Mekanik şanzıman sisteminin tümü, hassas bilyalı rulmanları ve süreç hassasiyetini benimser, ulusal standart seviye 7 dişli ve rafın hassas bir şekilde birbirine geçmesini sağlar.

4.Drive sistemi, Çin-Alman işbirliği ile planet redüktörü benimser. Giriş ve çıkış hatası sadece 16 ark. Yatay ve dikey dişli transmisyon yapısında, transmisyon yapısını CNC sistemi ile uygulama düzenini yapabilen otomatik kompanzasyon boşluğu cihazını arttırır.

5.Ana tahrik kirişi: Boyuna ray sıkma cihazı, eksantrik tekerlek sıkma cihazını değil, otomatik yönlendirme yapısını benimser. Otomatik kılavuz yapısı yay kuvvetine dayanır ve iki kılavuzda sabit yürümesini sağlar ve sıkı ve gevşek görünmeyecektir.

6.Tüm vida ve çelik yapılar, siyah veya krom kaplama işlemi kullanır.

Teknik parametre

YOK HAYIR | madde | Değer | birim |

1 | Enine kılavuz mesafesi | 3000 | aa |

2 | Etkili kesme genişliği | 2500 | aa |

3 | Boyuna kılavuz ray uzunluğu | 8000 | aa |

4 | Etkili Kesme Uzunluğu | 6000 | aa |

5 | Plazma kesme kalınlığı | Karbon çeliği ≤6 | aa |

6 | Meşale yukarı ve aşağı yükseklik | ≤150 | aa |

7 | Hız kesmek | 50-3500 | mm / dak |

8 | Sürüş sistemi | Step motor | |

9 | Yerleştirme yazılımı | STARCAM |

Özellikler

1. İyi sertlik, yüksek hassasiyet. Stresle başa çıkmak için VSR.

2. Çelik levha kaynaklı yapı, yüksek sıcaklıkta su verme, makine ömrünü garanti eder.

3. Dikey ve yatay sürücü.

4.Yerli step sürücü (isteğe bağlı olarak ithal sürücü sistemi).

5. Örnek ve kolay kullanımlı otomatik programlama sistemi.

6. CNC kontrolü.

7. CAM yerleştirme yazılımı.